Mobility

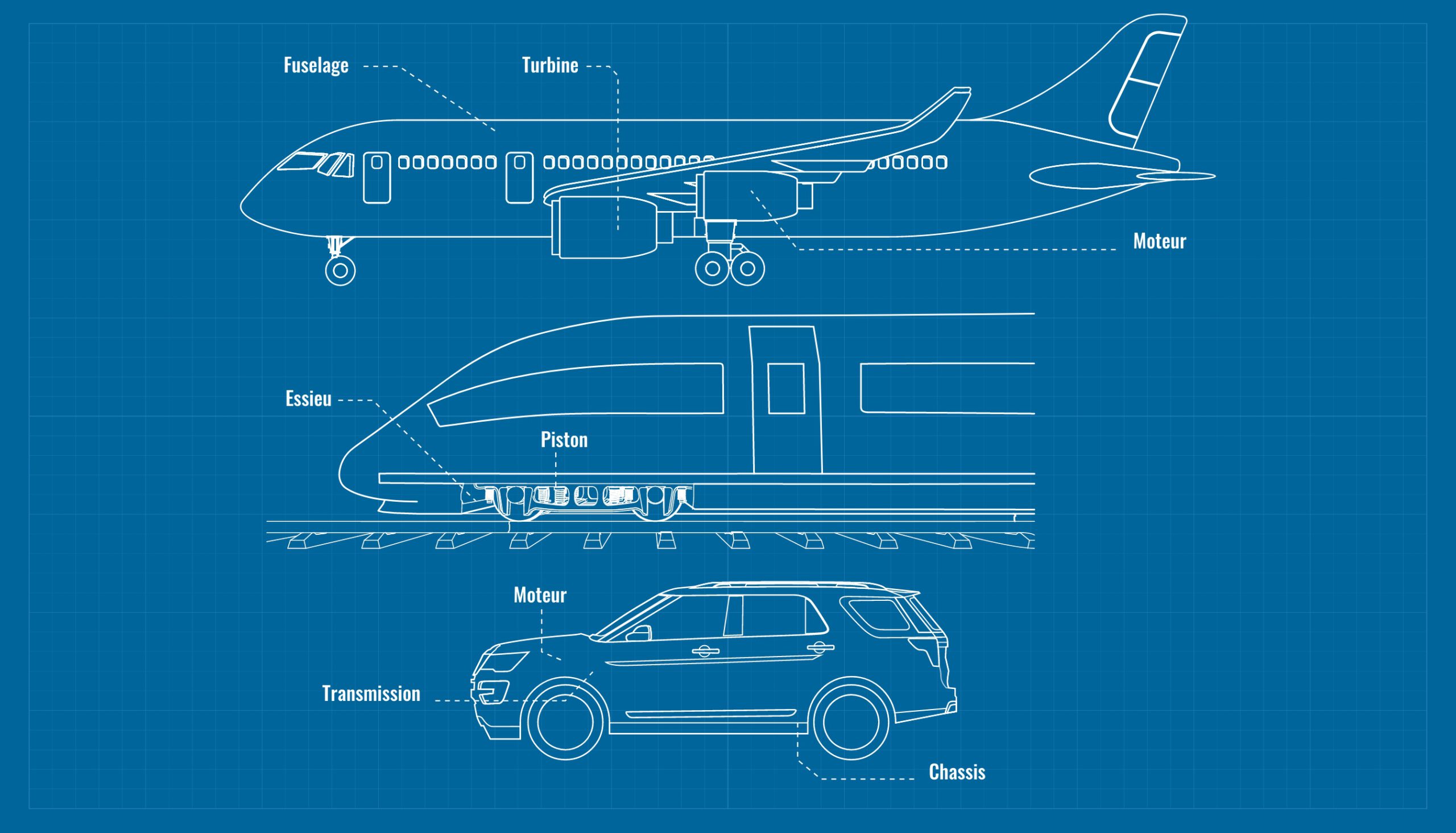

Aero, Auto, Train, Off Road

Mobility – McKinsey defines the market as “the market that includes public & private passenger transport as well as the transportation of goods”. As we enter the third decade of the 21st century mobility is reinventing itself through a rupture in technology. SUMCA as a tooling supplier has always been a source of innovative tooling solutions to help with subjects such as variability, output and reliability.

As a source of innovative solutions for variety of different production solutions SUMCA is preparing tooling for stamping, blanking and pressing technologies. Whether these are linked to temperature control in battery cooling, bipolar plate production or safety systems these are all new areas that complement our historic business covering lighting, ride control, braking and drive train.

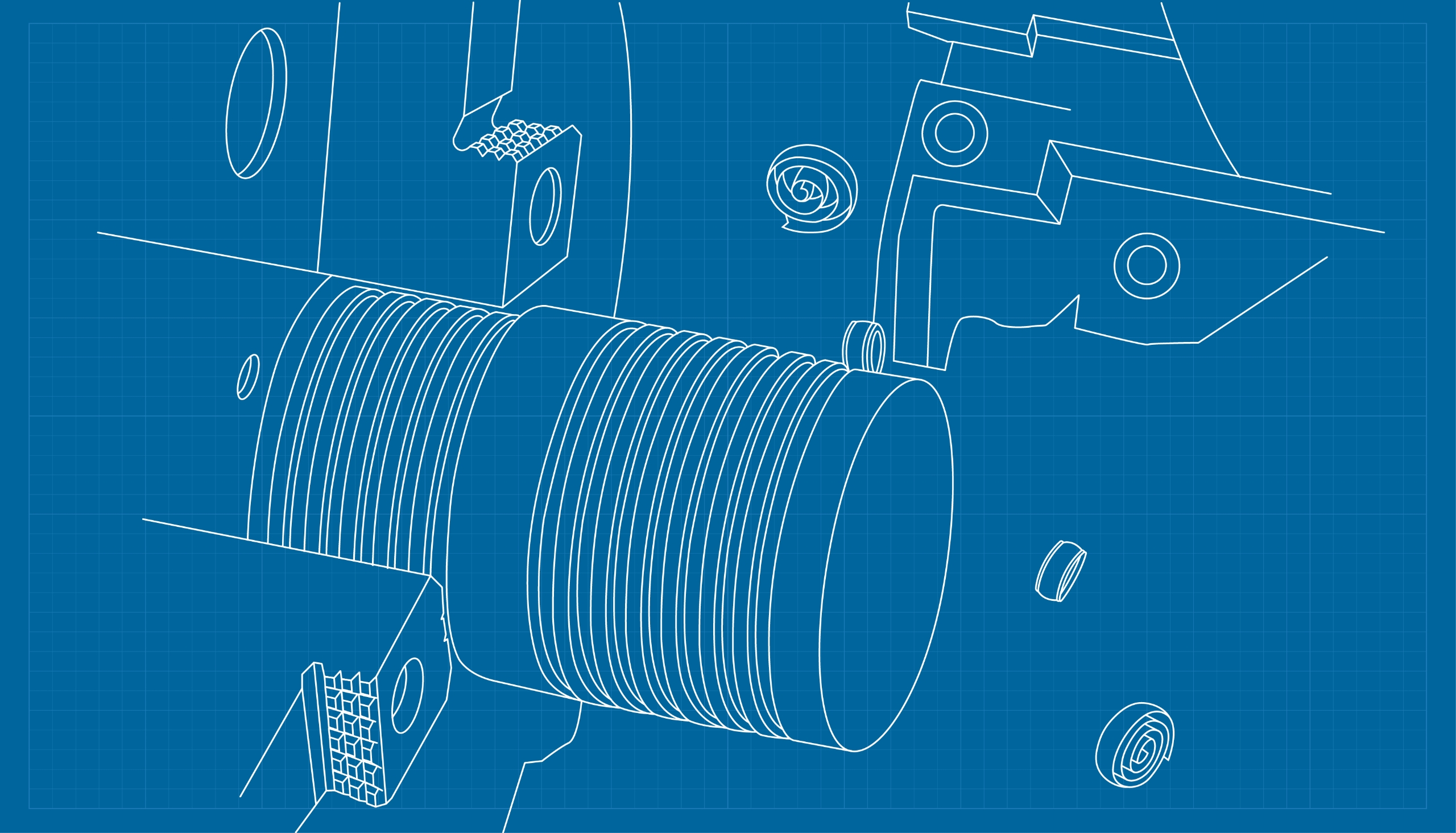

Carbide Cutting Inserts & Hard Metal Wear Parts

Carbide Cutting Inserts & Hard Metal Wear Parts

The compaction of powder to produce near net shape forms is exploited in many difficult to handle materials, carbide by its very nature is extremely hard and requires costly finishing operations.

This demands that tools are precise with extreme air gap consistency. We generate our air gaps through wire, five axis grinding, jig grinding and sink erosion.

With the development of our innovative and protected Geo Gleiss process we deliver tools that are geometrical perfect with a surface finish ~20 nanometers. This means mirror finishing with absolute precision equalling long runs between cleaning due to lower friction and an improvment in well defined cutting edges.

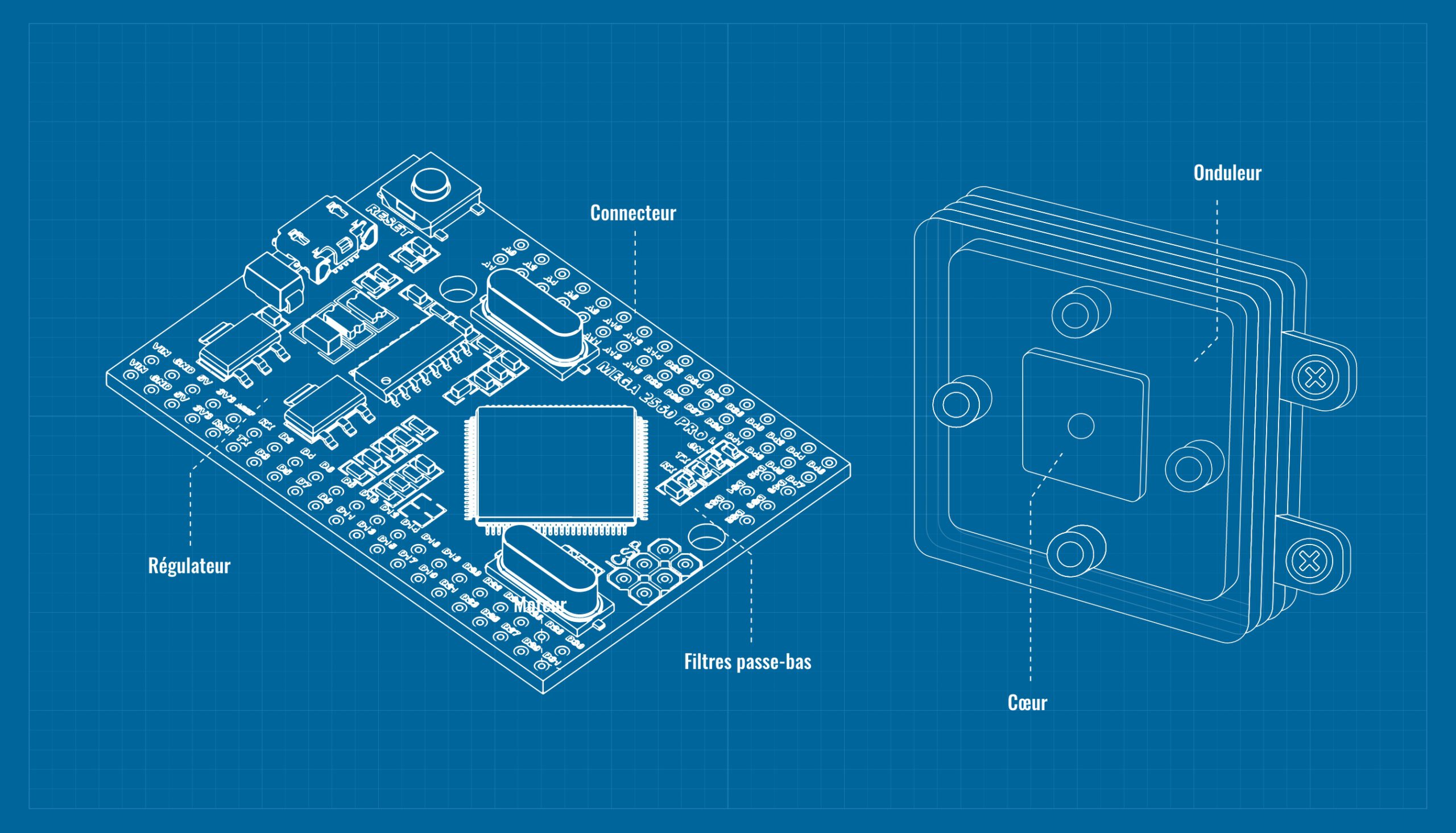

Electronics, Energy, Fuel Cell

Electronics, Energy, Fuel Cell

A key market for our workshops is the requirement for industrial companies such as those working in energy. Whether nuclear, wind or fuel cell generating electricity or the components that are used in switching from semi-conductors up to contactor for significant current we have solutions that can help with your tooling requirements. Our five axis tool production is in constant development with exciting innovations to support this rapidly growing market.

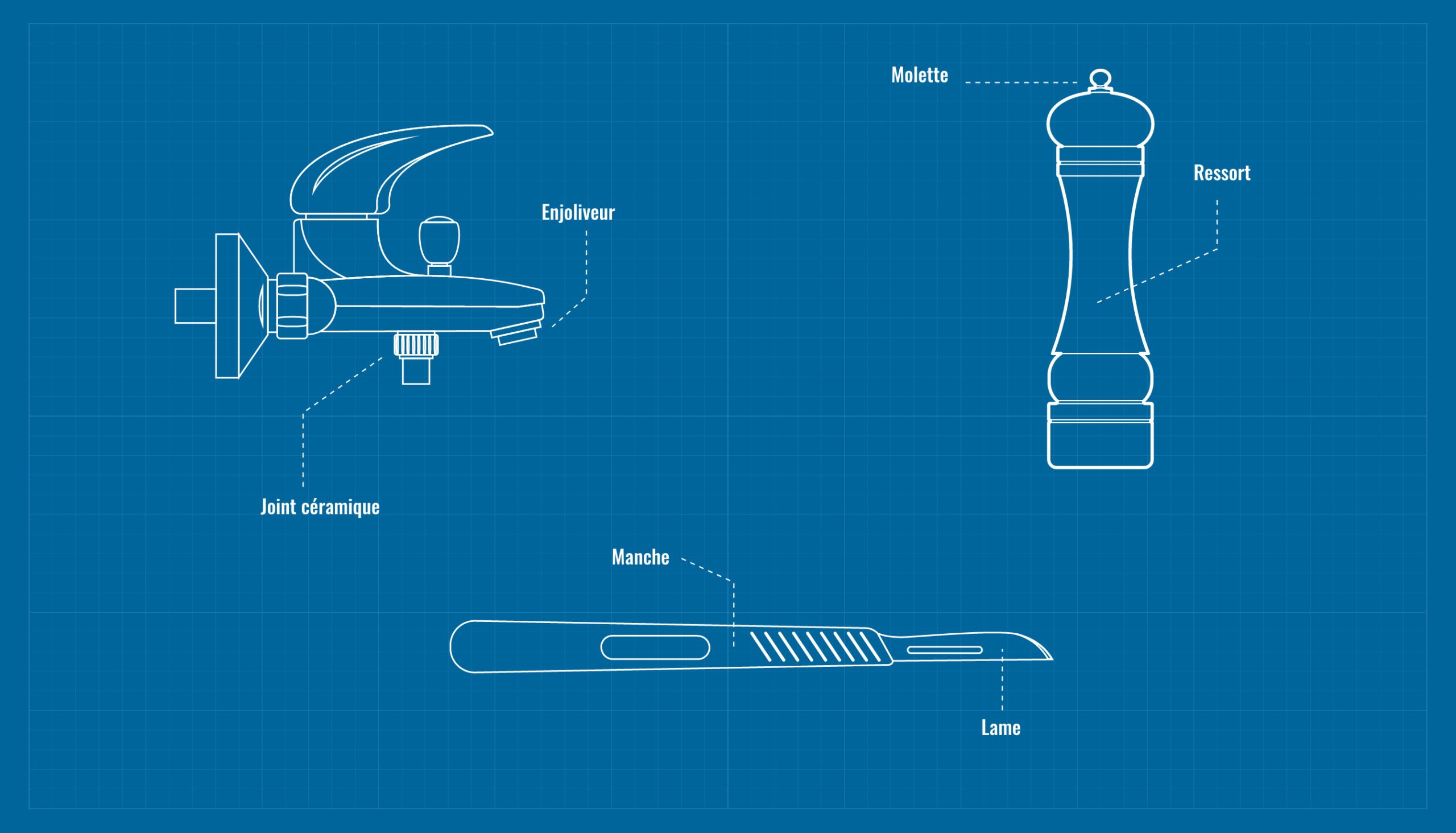

Medical and Consumer

Medical and Consumer

The global healthcare and medical markets are booming for many years due to wealthy but aging societies and driven by technical advancements.

SUMCA’s high precision tooling is used in the production of medical instruments, plates and screws for bone fractures as well as for tooth implants which are compacted from high tech ceramic powders.

Consumers can find products which are produced with SUMCA tooling almost everywhere, from the ceramic regulator discs which create the correct water temperature when taking a shower in the morning, in many electronic devices which we use during the day in the office and at home, the light that we switch on, as well as in such simple things like a ball pen.